Food Packaging Award

HOUSE Vermont Curry

- House Foods Group Inc.

- YAMATO-ESULON Co., Ltd.

To reduce CO2 emissions and the use of petroleum-based plastics, we have collaborated with Yamato-Esulon Co., Ltd. to introduce plant-based materials into the tray of our carton-type (230g) "Vermont Curry." This innovation has resulted in a reduction of petroleum-based plastics and the incorporation of plant-based materials. Despite being thinner than the conventional tray, its quality, including suitability for physical distribution and production lines, equals to the conventional product due to the incorporation of a resin mixture. We have already obtained the Biomass Mark 10 certification from the Japan Organics Recycling Association. We anticipate an annual reduction of approximately 206 tons of CO2 emissions as a result of this improvement.

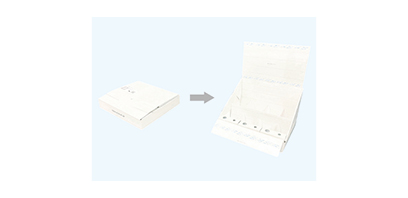

PIZZA HUT TRICK BOX HUT STADIUM BOX

- Rengo Co., Ltd.

- PIZZA HUT JAPAN LTD.

This pizza set box, containing three pizzas, was introduced during the 2022 FIFA World Cup and the 2023 World Baseball Classic periods. It was designed to instantly evoke the excitement of sporting events upon delivery. In addition, it can be transformed into a miniature stadium after its intended use. Beyond its role as a packaging and transport container, it can betransformed into a delightful tool that provides an engaging experience for gathering with friends and companions at sporting events. The packaging attracted significant attention from both the media and social media.

Lettuce Kururinpa Sheet

- SEIKOU CO., LTD.

We have introduced the 'Lettuce Kururinpa (Swiveling Around) Sheet,' which eliminates the need for packaging machines and allows even inexperienced individuals to easily wrap lettuce especially iceberg lettuce. These film sheets are stacked similarly to Post-it notes, with one end of each sheet adhered. To use, simply open one of the film sheets with the glued area as the starting point, place a lettuce on it, roll the sheet around the lettuce, and swivel it halfway around. This process provides a labor-saving packaging solution, making it easy and quick for anyone to package lettuce efficiently.

"Kayanoya Japanese Hot Pot Series" Paper Pouch

- Kubara Honke Group Co., Ltd.

- TOPPAN Inc.

- good design company

We have developed the standing pouch for "Kayanoya's Hot Pot Series' All 13 Products," focusing on dealuminization. For the surface layer, we have selected the unryushi paper to represent the image of the brand and Japanese cuisine. For the intermediate layer, we have chosen the optimum material including high-quality paper and thickness, which has solved all the challenges such as adequate preservation of contents, stability, decoratavility (chromogenic property) and availability in manufacturing, even though aluminum foil has been eliminated. Thus, the amount of plastic used per sheet has been reduced dramatically by about 30% in the theoretical value. Moreover, the synergy effect between the eye-catching color of the Japanese paper pattern as well as the brilliant product and the improved folding manner has drastically improved eye-catching effects at stores and added a value as gift packaging.

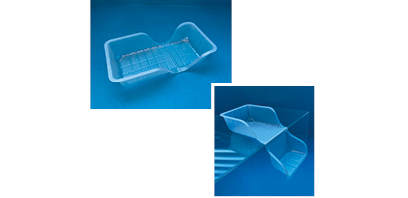

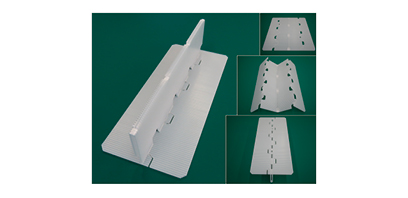

3D Trimming Tray (Bendable Tray)

- ITOCHU PLASTICS INC.

- FamilyMart Co., Ltd.

- GINPO PACK Co., Ltd.

We have developed a foldable tray for new products in the convenience store industry using a special trimming process. Through a three-dimensional trimming process, we have successfully achieved a balance between a sleek appearance and effective content protection. Designed for use in a frozen and chilled temperature zone, we have employed materials commonly used for frozen ice. Additionally, the tray features an edge designed for automatic dispensing. This design allows for easy removal of the product from the bag and enables clean consumption by folding the tray, keeping hands clean and convenient.

ORGANIC HERB SALT

- S&B FOODS INC.

- TOPPAN Inc.

This packaging has reduced the amount of plastic used by approximately 37% compared to conventional design by incorporating paper as the primary printing base material. We have employed a transparent barrier film called GL BARRIER for primary packaging to contact the food, along with a reclosable zippered pouch, eliminating the need for individual packaging. This design results in an easy-to-use package with excellent preservability and functionality, all while being primarily composed of paper. Furthermore, our paper package utilizes water-based flexo printing, which is expected to reduce CO2 emissions by approximately 20% compared to typical plastic packaging. Water-based flexo printing enhances print quality on paper, improves visibility of micro characters, and reproduces designs with vibrant imagery.

HONDASHI® 8g×14 Sticks, 8g×26 Sticks

- AJINOMOTO CO., INC.

- FUKUSUKE KOGYO CO., LTD.

The large bag containing 8g 'Hondashi® sticks' has undergone a transformation, now housed in a paper package. This change has led to a substantial reduction in plastic usage, approximately 32%, which translates to about 32 tons annually when combined with the stick and pouch packages, compared to the current plastic packaging. Furthermore, with a focus on enhancing the usability and playful aspect of paper, we have introduced perforated lines and a 'coloring picture' on the reverse side. By developing packaging and studying industrialization over about two years, we have introduced paper packaging with a quality equivalent to plastic packaging and have achieved the introduction into the market in partnership with packaging material suppliers and packaging factories.

Paper-based Packages for oh'my Pasta Series

- NIPPN CORPORATION

- Kyodo Printing Co., Ltd.

In the launch of our 'Happy and Natural Blessing Series,' a new product line focusing on deliciousness, health, and environmental friendliness, carrying the message of 'happiness for both people and the earth,' we aimed to develop eco-friendly 'paper' packaging. We conducted extensive testing to achieve the utilization of a horizontal pillow machine, a previously unprecedented step in our efforts. This endeavor has enabled us to introduce primary packaging for food products made from FSC certified paper, incorporating plant-based biomass ink as part of the raw materials. Leveraging our gravure printing expertise, we have achieved excellent print quality while maintaining high resistance to abrasion.

Confectionary Packaging Award

"smoke Cheesecake" Octagonal Cosmetic Box with Ice Pack Space

- Hinode Shiki Kogyo Co., Ltd.

- mirai Co., Ltd.

We have improved the packaging for cheesecake to create assembly work at our labor support office. The octagonal design offers a simple yet elegant appearance. It provides ample space for cold insulators on both sides and can be made from single sheet even for cakes with unique shapes. This design emphasizes efficient material usage and easy access to the cake by simply opening the flap and being flattened in four directions. We have also paid attention to the surface texture and incorporated window holes on the top surface, which showcase our shop's three-dimensional logo by revealing the inner flap in the background. This packaging not only embodies surface texture but also combines simplicity with high-quality aesthetics.

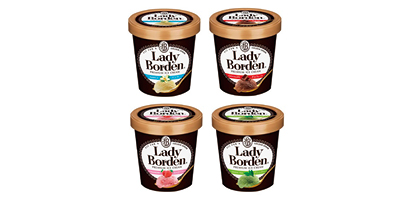

Reducing Weight of Lady Borden Ice Cream Caps and Improving Transportation Efficiency

- LOTTE CO., LTD.

- TOKAN KOGYO CO., LTD.

We at Lotte Co., Ltd. have established the Lotte Plastic Basic Policy and endeavored to reduce the amount of petroleum-based plastic used. Furthermore, as part of our commitment to realizing a low-carbon society, we have conducted a thorough review of transportation efficiency to address reductions in CO2 emissions during transportation. For the package of the "Lady Boden Pint" ice cream, we have reduced the lid thickness, made minor adjustments of the lid fit diameter, so that the fit strength between the lid and the cup becomes the same, and have reduced the amount of petroleum-based plastic used by about 23% from 12.9g to 9.9g for the lid weight. Additionally, we have optimized the arrangement of eight ice cream cups within the cardboard case, resulting in a remarkable increase in transportation efficiency, up to approximately 108%, which contributes significantly to the reduction of CO2 emissions.

Four Types of Small Sweet Packages

- Bourbon Corporation

- KANEKA CORPORATION

- Nippon Paper Industries Co., Ltd.

We have developed outer packaging that significantly increases the use of paper to address the plastic waste issue. To increase the paper usage, we have incorporated heat-sealing paper for the outer packaging, a collaborative effort with Nippon Paper Industries and Kaneka. This paper is bonded using Green Planet®, a 100% plant-based biodegradable biopolymer developed by Kaneka. This innovation has not only contributed to reducing CO2 emissions but also to preserving the global environment. Furthermore, we have utilized ink-jet printing with water-based ink, which is free from volatile organic compounds (VOCs).

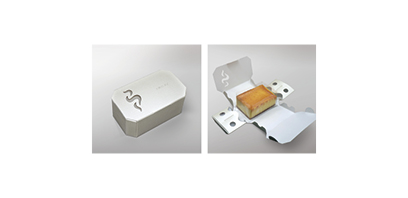

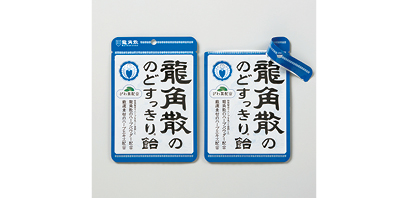

Ryukakusan No Nodosukkiri Ame Zipper Pouch

- RYUKAKUSAN CO., LTD

- Dai Nippon Printing Co., Ltd.

This long-standing product is cherished by individuals of all ages, both men and women. With user convenience in mind, we have introduced 'multilevel laser processing' to the opening section of the zippered pouch. It is designed to open easily by pinching with your fingers, thanks to the differences in level at the mouth of the pouch. Additionally, the inclusion of a 'fountain-type notch' results in an elegantly curved cut end on the pouch, which significantly reduces the risk of hand injuries. Biomass PET is applied for eco-friendly solutions.

Paper Tray for Japanese and Western Sweets

- TOKAN KOGYO CO., Ltd.

- Sopak-Kanemitsu Co., Ltd.

We have initiated the development of the 'paper tray for Japanese and Western confectionery,' which not only promotes environmental friendliness but also enhances promotional efforts, all while maintaining the performance standards of conventional plastic trays. Made entirely of paper, this tray significantly reduces plastic usage, lowers CO2 emissions, and simplifies recycling processes. This paper tray boasts handling performance equal to that of its plastic counterpart, making it suitable for individual use as a sweets tray.

Beverage Packaging Award

Whisky "RIKU" in New Pouch for High Concentration Alcohol

- Kirin Holdings Company, Limited

- Kirin Brewery Company, Limited

- Kyodo Printing Co.,Ltd.

To introduce pouch packaging for 50% alcohol content whisky, 'Riku,' we have carefully designed the layer composition to ensure strong adhesion between layers. The pouch features a bottle mouth shape for improved pourability, while its corners have been rounded to prevent finger injuries and minimize damage during transportation. We have also incorporated Braille to prevent accidental swallowing by the visually impaired, as well as a hook hole for potential individual sales. Compared to traditional glass bottles, our pouch packaging has significantly reduced CO2 emissions during manufacturing and transportation, reaching a reduction of about one-hundredth. We have also utilized biomass-based raw materials for certain films and printings. Additionally, our pouch packaging allows for transportation via non-standard-sized mail and facilitates cost-effective large-scale campaigns.

Package for MAWSIM, a Craft Gin That Uses Square Paper Tubes

- NIPPON KAKO-KIZAI. CO., LTD.

- SUNWASPA Inc.

- DesignWater

The packaging for craft gin 'MAWSIM' is crafted from a square paper tube which is eco-friendly and recyclable made from 100% recycled paper. Both the main body and the top and bottom lids are made of this square paper tube, embodying a unified design. Our commitment to environmental consciousness is reflected in the minimalist approach of simple printing and decoration, complemented by our brand label on the square paper tube. This approach maximizes the texture of the square paper tube, resulting in a dynamic and captivating design. In the future, a 'bottle U-turn system (Reuse)' is expected to be implemented.

NEW ILOHAS PET BOTTLE

- Coca-Cola Tokyo Research & Development Company, Limited

With 'Ilohasu,' renowned for its exceptional taste and eco-friendliness, we have introduced a new PET bottle that incorporates an innovative aspect of 'comfort.' This bottle showcases a chic 'label-less look' design with a refreshing appearance reminiscent of a flowing stream. The label located at the lower area of the bottle emphasizes the transparency associated with natural water. This fresh design allows for a seamless flow of natural water into the mouth, enhancing the taste and comfort of each sip. Furthermore, once the contents are consumed, the bottle can be easily flattened for convenient recycling of resources. The materials used is 100% recycled PET bottle.

Mineral-in-water Cap Minel ~Twist ! change! minel!~

- SUNTORY HOLDINGS LTD.

- Vessl, Inc.

We have introduced the packaging designed for our unique product which can transform ordinary tap water into delicious new water enriched with "plant mineral essence" called 'minel' which has been developed independently. To spray "plant mineral essence" into water, we have employed a new cap developed jointly with the U.S. Vessl Inc. The process is simple: just fill a dedicated plastic bottle with tap water or clean drinking water, attach the specially designed cap, and twist it. With a refreshing sound, 2ml of our 'plant mineral essence' contained within the cap is sprayed into the bottle. In an instant, the ordinary water in the bottle is transformed into a refreshing and flavorful drink. The minel cap is palm-sized, and the dedicated bottle can be used repeatedly after a wash.

Coffeeloop Cup

- ASAHI YOU. US, LTD

- Compass Group Japan Inc.

- Menicon Co., Ltd.

In the Coffeeloop project, which aims to establish a platform for creating a cycle using coffee grounds as valuable resources, we have initiated the development of Coffeeloop cups. In collaboration with Compass Group Japan Inc., a major operator of school and company lunch services, we have utilized coffee grounds discarded from major IT companies. By reusing the cups repeatedly as commercial utensils and recycling them through recoating and material recycling based on their condition, we aim to establish a circular economy. To enhance their strength, we apply surface coating by skilled artisans from the traditional Yamanaka Lacquerware craft, and we also incorporate hinoki cypress lumber sourced from forest thinning. Additionally, we use recycled polypropylene derived from unused scraps generated at Menicon Co., Ltd.'s contact lens factory.

Cosmetics Packaging Award

KANEBO BRIGHT FUTURE BOX

- Kao Corporation

- UEROKU PRINTING CO., LTD.

- NAGOYA MOULD CO., LTD.

We have introduced an innovative 'mono-material package' for makeup products, where all constituent parts are crafted from nature-derived 'paper.' Instead of using a traditional clasp structure with a hook, this compact features a paper sleeve that not only prevents accidental openings but also facilitates smooth and easy removal and insertion, thanks to cleverly designed paper textures and patterns. The tray for containing the eyeshadow utilizes pulp mold technology, allowing us to shape paper into three-dimensional forms. When selecting the material and shape for this molded pulp, used as primary packaging, we have considered its properties to accommodate content involving moisture and oil. By overcoming the inherent limitations of paper, we have successfully created a container composed entirely of paper material.

Pharmaceutical and Medical Packaging Award

Drug Package lnsert lntegrated Paper Container of Liquid Bandage

- Kobayashi Pharmaceutical Co., Ltd.

To address the issue of product misuse without reading a package insert, we have provided explanations on the inner surface of the package. The packaging is designed to be opened from the bottom of the case, making the usage instructions easily visible to users. Additionally, the removal of the insert has resulted in cost savings and reduced CO2 emissions. This package design with a header is commonly used in over-the-counter medical products, making it applicable to a variety of pharmaceutical products as well.

Toiletry Packaging Award

Umi No uruoiso

- Kracie, Ltd.

- TOHTO MOLDING CO., LTD.

With the product's redesign, we have introduced a 500ml bottle composed of 51% recycled beverage caps, 40% biopolyethylene, and masterbatches, that eliminate petroleum-based plastics. The caps used in this bottle are sourced from discarded caps at a bottle beverage filling facility. To ensure a stable supply of recycled materials, the caps are recycled not in a single color but in composite colors. As the recycled material naturally has a dark green color, it is incorporated into the intermediate layer of the bottle's three-layer structure. It is then sandwiched between the inner and outer layers of biopolyethylene to conceal the color.

Biore u the body

- Kao Corporation

To standardize 'friction-less washing,' we have incorporated our uniquely developed pump foamer, which increases foam volume by 1.5 times, ensures a stable form, and enables comfortable palm washing experience. The bottle is made from 100% recycled plastics, specifically polyethylene terephthalate (PET). We have minimized plastic usage by embossing the brand logo on the container and reducing the label area compared to conventional designs. The bottle features a wide mouth for easy refilling, and the pump is carefully designed to provide a comfortable grip for the palm and easy pressing. To fully utilize the transparent properties, we have boldly displayed graphics on the back label, creating an aesthetically pleasing and transparent space.

Easy Mixing of Hair Care Mask and Oil in One Package "JOY CLEAR"「ICHIKAMI THE PREMIUM OIL IN HAIR TREATMENT MASK」

- KANAE CO., LTD.

- Kracie, Ltd.

As a method of caring for highly damaged hair, we have unveiled a secret technique commonly used by professionals - the blending of oil with a hair mask - now available in a single package. The hair mask and oil, each sealed in separate pockets, are mixed within the package 'just before use,' allowing for the optimal results of each component. Users no longer need to measure the quantities themselves. Two liquids are mixed simply by pushing the oil-filled pocket and breaking a weak seal in the middle, enabling the precise blending of the ingredients. The packaging features a 3-dimensional pocket design with a button-like bulge that fits easily between your fingers, simplifying the activation. Made of flexible film, the entire package is soft, making it easy to mix the hair mask and oil while monitoring the mixing procedure from the transparent side.

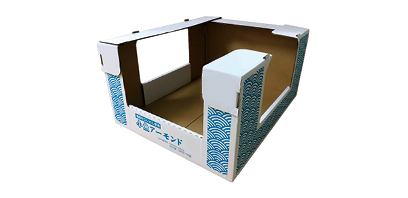

Paper Conversion of Bottle Set Package

- Unilever Japan Service K.K.

- THE PACK CORPORATION

To address environmental concerns, we have undertaken the challenge of replacing plastic bags in bottle set packaging with paper packaging. The area to support the bottles is created by folding the paper at the bottom and reinforced with several ruled lines to securely accommodate and hold the rounded bottles. Additionally, the bottleneck is double-protected to strengthen the packaging. The pumps are left uncovered to ensure ease of setting up the packaging. This packaging features a simple, glue-free structure using a single sheet of paper, providing both ease of assembly and strength (design rights have already been secured).

Paper Cube Package for Baby Milk Lotion

- Pigeon Home Products Corporation

- TOPPAN Inc.

This is a paper container with a pump designed specifically for the 600g large-capacity "Baby Milk Lotion" for retail stores. In comparison to conventional plastic bottles, our design significantly reduces the use of plastic resin. Furthermore, the paper's cut surface in the bottom remains shielded from contact to facilitate the usage in areas with exposure to moisture, such as bathrooms. The improved pumping mechanism has enabled both leak prevention during use and the efficient utilization of the entire product content. In addition to our product innovation, we are proud to be actively engaged in the Japan SDGs Action Platform Project in Fuji City, where we contribute to the "paper container recycling project"

Magnifique

- KOSÉ COSMEPORT CORP.

We have developed a gender-neutral hair-styling series inspired by the concept of natural beauty. The jar bottle features a matte texture that provides a natural feel, and its rounded corner cube design allows it to fit comfortably in your hand. The bold brand logo and line color represent a simple and gender-neutral aesthetic. Additionally, we have differentiated the bottle colors based on the type of product (White for wax, blue-gray for gel grease, and milk white for balm). These bottles can be stacked conveniently anywhere.

Daily Necessities and General Merchandise Packaging Award

PureOra36500 CREAMY TOOTHPASTE

- Kao Corporation

- YOSHINO KOGYOSHO CO., LTD.

- Fuji Seal, Inc.

We present an innovative toothpaste packaging concept comprising three essential elements: a button-type pump, a pouch, and a holder. With our button-type pump, dispensing toothpaste becomes effortless―simply touch the button with your fingertips, and the toothpaste is squeezed out without the need to move the pump nozzle. When combined with an airless-structured pump and a pouch, our design ensures that you can fully utilize the content by easily pushing the pump. Moreover, the holder not only provides a convenient way to hold the pump but also keeps the product upright. Once the pouch is empty, you can replace it with a new one while retaining the pump and holder for repeated use.

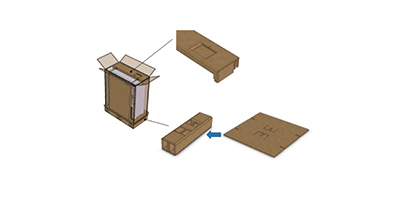

Amazon SIOC-compliant box for 3M Greener Clean Net& Mesh

- 3M Japan Limited

- Rengo Co., Ltd.

For the sale of the "3M Greener Clean Net & Mesh" on Amazon, we have developed packaging that complies with the SIOC Certification Standards which eliminates the need for additional packaging and can be shipped using packages from the source of manufacture, adhering to the size standard of at least "230mm in length, 150mm in width, and 2mm in height." We have chosen the cost-effective N-type box which are manufactured only by punching process without gluing and innovated a new design with varying sizes in the flap on the top and the body. The flap size aligns with the SIOC Standard, while the body size matches the product dimensions precisely. As a result, both components are optimized in size, eliminating the need for cushioning materials. During assembly, folding the side faces automatically folds the corresponding adjacent faces simultaneously, simplifying the process. To secure the top flap, the hamegoroshi (fixed fittings) method is applied which eliminates taping.

Star-shaped Packaging for "Nijiiro Plates" with a Sustainable Material

- Crown Package Co., Ltd.

- SANYU RAITO CO., LTD.

To showcase our educational toys at an exhibition in France, we have improved the packaging based on the concept of a 'charming paper-based box.' To create a sustainable package, we have selected 'Colorful Wish,' a recycled paper made from paper cranes. While reserving the image of the current plastic packaging, a star-shaped box has been developed using micro flute cardboard―an ultra-thin, shock-absorbent material. This innovation not only enhances the cushioning properties but also contributes to reducing plastic usage. The three-dimensional star-shaped design asserts the uniqueness of the package, and the paper cranes express 'a wish for peace and recycling of resources.'

Cubic Coloring Box Kit

- Sagasiki Co., Ltd.

- Moomin Monogatari, Ltd.

This is a papercraft work kit designed for children, featuring Moominvalley Park to help them appreciate the world created by Tove Jansson, the author of the Moomin series of picture books. Within this kit, beloved story characters are neatly lined up and ready for children to color. The kit offers an enjoyable experience in crafting a theater stage, achieved through cutting, folding, assembling, and inserting paper sections following the illustrated instruction manual provided. This paper-made kit includes unpainted paperboard prepared for coloring, the base box designed to store toy parts, and disposability featuring the advantage of the material.

Non Lami Pack

- Jbfsupply Co., Ltd.

The innovative Non Lami Pack has been developed for stationery and daily sundries. It is created by bonding oriented polypropylene (OPP) film and paper without the need for lamination. More than 60% of the material used is paper, and the content is visible from the outside. The absence of a lamination process, as heat sealing is not required, has allowed us to increase paper usage significantly. We utilize offset printing, resulting in cost savings for original proof production and making it suitable for small production runs. Unlike products that require paper/film rolls and demand larger minimum production lots, this eco-friendly solution minimizes waste and disposal.

SOFLAN Airis

- LION Corporation

We have developed a new fabric softener liquid called 'Airis' with a fresh concept "Airis Experience, relieving and alleviating cleaning job and daily chores." The bottle is transparent, allowing users to easily check the remaining liquid level for convenient refilling. Its square shape is designed for convenient side-by-side placement. It is made from biomass PET, with the addition of a UV-absorbing agent to protect the liquid, as both the liquid and bottle are transparent. The label features a skeleton design and is applied using the back printing method. The pouch packaging boasts a transparent design achieved through matte varnish, enabling users to view the contents from the outside. UV-absorbing inks are used for the pouch printing to protect the liquid inside.

Hotel Amenity Toothpaste Paper Sachets

- Kokusai Kogyo Co., Ltd.

- SASAKI CHEMICAL Co., Ltd.

- TOPPAN Inc.

The plastic tube packaging for complimentary hotel toothpaste has been replaced with a new design utilizing a combination of paper and film, leading to a reduction in plastic usage and increased paper utilization. We use water-based flexo printing for the packaging, effectively reducing CO2 emissions. Additionally, we have incorporated a transparent barrier film called GL BARRIER to enhance its barrier performance. These measures have been taken to ensure the preservation of toothpaste quality.

Gift Packaging Award

![House Shaped Gift Package [Qummy (Spoonful of Excellence Gift Box)]](images/image84.jpg)

House Shaped Gift Package [Qummy (Spoonful of Excellence Gift Box)]

- Nippon Tokan Package Co., Ltd.

- Kewpie Corporation

This baby food gift packaging has been developed with the aim of supporting inexperienced parents and guardians. The gift box features a unique hexagonal shape with two corners cut off, resembling a house motif, which effectively captures consumers' attention when it's sold online. When one bottle is removed from the box, consumers will discover heartfelt messages for parents and guardians who are busy with childcare, accompanied by illustrations in each section. These messages can be read one by one, allowing them to appreciate their baby's daily growth. By using a house motif for the packaging and delivering messages from this perspective, the package design conveys a message of encouragement to parents and guardians. It encourages them to transform their homes, where they spend much of their time raising their children, into happy and comfortable spaces rather than lonely ones.

Packaging for Watch Shipping Made from Cotton Scraps

- Seiko Epson Corporation

- Epson Sales Japan Corporation

Developed as a packaging bag for the direct delivery of watches from Seiko Epson Corporation to end-users. Upcycling is achieved through the utilization of offcuts from sewing companies. This bag is reusable for storing watches, wallets, and other accessories. Its compact design features the pristine white hue of its primary material, cotton, to convey a neat and sleek impression. It boasts an unprecedentedly pleasant texture, is resistant to bending and tugging, and maintains its functionality even in high-temperature and high-humidity conditions.

Paulownia Style Gift Box Made of Paper

- Wacon Co., Ltd.

- KOKUBO FARM

This paper box has been developed to replicate the luxury of a wooden box. Utilizing paper enables flexible design and structure, while also offering eco-friendliness due to its recyclability. The lid's surface features embossing, providing it with the texture and appearance of crocodile leather, resulting in a stylish and distinctive packaging solution. Furthermore, the cost per unit is lower compared to paulownia boxes.

Umenoyado Sake Brewery PARLOER ARAGOSHOI Online Limited Package for 4 Types

- UMENOYADO BREWERY Co., Ltd.

- TAKAGI-HOSO CO., LTD.

Umenoyado Sake Brewery has introduced a fresh venture in its 130th year with the launch of the brand "PARLOR ARAGOSHOI." Based on the new concept of "alcohol for eating," we have created a standardized gift package for the brand's four novel products. The choice of package size and materials has been made to harmonize with the brand's essence and colors, imparting a sense of luxury upon opening the cap. The packaging design and structure have been considered to simplify assembly procedure and to endure the shock during the transportation. Currently, out of the four gift variations, the two with notable sales are presented in exclusive packaging.

Mail-order gift with POP display to Give a Sense of Surprise

- Crown Package Co., Ltd

- P2C Studio Co., Ltd.

This box is a special edition exclusively designed for Christmas available through mail order. The exterior artwork captures the essence of Christmas, with graphics that make use of the difference in material and texture between the outside and the inside. Designed to fold compactly to optimize inventory space, enhance transportation efficiency, and be sealed without the need for packaging tape, thus reducing materials and CO2 emissions. Upon unzipping and lifting the lid, a three-dimensional Christmas tree pops out, delivering a delightful surprise. When the box is opened, the front side also opens to allow easy access to the contents. The box is made of E-flute corrugated cardboard and is recyclable.

Gift Presentation Box with Can Dent Reduction Effect, "Kanshozai"

- Rengo Co., Ltd.

- ASAHI SOFT DRINKS CO., LTD.

We have developed a decorative box designed to safeguard beverage cans inside, preventing them from getting dented while maintaining an attractive exterior appearance for gifting purposes. Our approach emphasizes eco-friendliness by focusing on modifying the box's shape without the need for additional reinforcement materials. To reduce the occurrence of can dents, we have created a hollow center section in the box, specifically targeting the areas where the cans are most vulnerable to external shocks. Additionally, we have extended and processed both sides of the insert to provide cushioning functionality, effectively concealing the underlying color and enhancing production efficiency.

PAPER CRAFT PACK

- Sasatoku Printing Co., Ltd.

This packaging is crafted using papercraft data available for download, which is easy to use. We have incorporated new features like 'Wrapping with Your Heart' in gift-giving and unique packaging technology, resulting in fresh content that offers an enjoyable wrapping experience to our users. To enable users to create their own products with a DIY approach, we have prepared a variety of fun specifications available in a series. Our original seasonal designs are included, making these products suitable for gift-giving on any festive occasion. Our latest design technology provides the thick printing paper with an enough strength as the packaging.

Human and Eco-friendly Cutlery and Tumbler Gift Cases

- CHUOH PACK INDUSTRY CO., LTD.

New gift sets have been developed on the theme of novel design, environment, and waste disposal. On opening the gift box, the receiver will instantly notice what is inside; cutlery and tumblers. This gift case is all made of paper; cardboard is used for directly wrapping gift items, and single-faced corrugated board is used as wrapper. Naturally, the box is well recyclable. Everyone can break down the box into a compact size simply by pulling tabs on the both sides. This product is gift wrapping with reduced burden on people and the environment.

FRIXION BALL KNOCK ZONE × ANNA SUI Collaboration Package

- PILOT CORPORATION

- TANAX. INC

This product is the outcome of the collaboration project between the Friction Ball Knock Zone ballpoint pen and Anna Sui. The newly completed package contains a set of a ballpoint pen and refill leads. From designers' wish to have users keep the purchased packages and not throw away, it is intended that the package can be used for a secondary purpose. It features a graphic design of the Anna Sui butterfly image and a window to show the product inside. As a result, the package is ready for the secondary use as an accessory box or a pen case.

POP Packaging Award

Signboard without Trash

- Sony Customer Service (Japan) Inc.

Our new packaging box can now transform into a standing signboard. The stand of the signboard and the packaging box were previously separate components, but we have integrated them into one, resulting in a 34% reduction in cardboard usage. This innovation ensures zero waste generation after assembly and also eliminates the cost and workload associated with disposing of packaging, all while maintaining the functionality of the signboard. Additionally, by optimizing the size of the packaging box, which was originally oversized to protect the stand, we have reduced the box's volume during delivery by 53%.

Jumble Convertible Carton

- Prima Meat Packers, Ltd.

- Rengo Co., Ltd.

This eco-friendly jumble display furniture also serves as a shipping carton. Its outer cover protects the display during transportation. Once assembled, it supports the display as a bottom plate without exposing any transportation marks, ensuring an excellent display appearance in stores and enhancing promotional effectiveness. Additionally, the zipper part remains attached to the display after assembly, enabling complete recycling of all components after use.

Dual Use Carton Box

- ISEHAN Co., Ltd.

- Links Co., Ltd.

Our newly improved transport box seamlessly transforms into display furniture at stores. When assembling the display, the delivery box directly converts into the display box, minimizing waste generation. No cutters or additional tools are required to open the box. This packaging solution can include signboards, partitions, stepped platforms, and product testers within the box. The design accommodates various POP sheets, enabling versatile usage for different purposes.

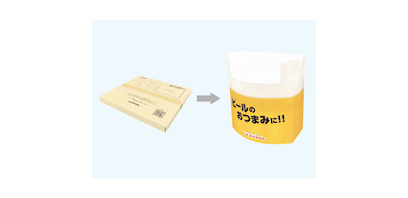

Transport Box Integrated Beer Display Stand

- Prima Meat Packers, Ltd.

- Links Co., Ltd.

The transport carton transforms into jumble display furniture. The carton and furniture are integrated, so there will be no carton waste when assembling the furniture. Customizations in size, shape (half circle, square, pentagon shape), and backboard are available according to the goods to transport. Assembling the furniture is simple, single-step process, requiring minimal workload at the store.

WHOMEE Item Set Packaging at Pharmacy

- Nuzzle Inc.

- TANAX. INC

We have developed a new packaging solution aimed at enhancing the convenience of in-store product displays. This innovative package addresses several key points: simultaneous installation of both the display and products, quick and easy setup of the display and products, and safe transportation of goods from the shipper to each store. The package is designed to include a wide variety of goods already set on the display stand before delivery, allowing for instant display setup upon opening the box. This eliminates confusion and errors during the display setup process at the store, thereby reducing the workload of busy workers. Furthermore, this approach minimizes disparities in the quality of store presentation among individual workers, ensuring a consistent and high-quality store appearance.

Transport Packaging Award

DP Lock

- Daio Package Corporation

We have enhanced the bottom-lock corrugated box to improve its bottom strength. Conventional design resulted in a significant wasted area and required two separate processes: die-cutting and machine-based body gluing. The improved design generates minimal waste and can be manufactured in a single process using a box-making machine (Evol), allowing for the production of cost-effective products. The bottom features larger overlapping areas, resulting in a 64% increase in strength compared to the conventional design, thus ensuring safety.

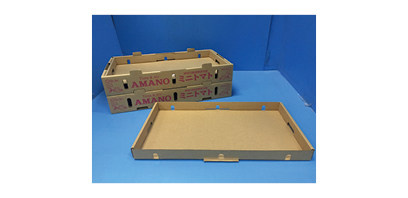

3 Ways to Use Tomato Case

- Nippon Tokan Package Co., Ltd.

- Nippon Contec inc.

- Amano Management Service Corporation

This is the packaging of 4 kg cherry tomatoes with the aim of enhancing its strength, making it suitable for both large and cherry tomatoes' application, and adaptable for 2 kg shipments as demanded. To achieve this, we have reviewed the structure of the outer box to have removed the partitions and pads from a tray for 2 kg shipments. For shipments of 4 kg cherry tomatoes, two trays, each containing 2 kg, can be stacked within the outer box. The tray is designed to prevent damage to the cherry tomatoes in the lower section. In the case of 4 kg shipments of large tomatoes, only the outer box will be utilized.

ECO COOL SNOW + WEB6

- IZAK Co., Ltd.

A fully recyclable standard container with effective cold insulation and wet resistance from condensation for transporting frozen products, the "Eco Cool Snow," boasts enhanced cold insulation properties thanks to its double-layered structure. This structure consists of an outer box and an inner box, eliminating gaps in insulation. The inner layer incorporates a newly developed water-resistant liner called "WEB6," which does not require resin lamination or coating processes. It maintains strength even in wet conditions and offers excellent circular recyclability, significantly reducing CO2 emissions. The outer layered was equip with a layer made from "Eco Cool," featuring a hybrid structure that combines decorativeness and effective cold insulation properties. This makes it ideal for shipping, taking out from the shop, or using as a gift box.

Export Box for Product-of-Japan Sweet Potato

- Rengo Co., Ltd.

- Wismettac Foods, Inc.

- Tokyo Seika Co., Ltd.

- Nomura Research Institute, Ltd.

In response to the increasing demand for Japanese agricultural products overseas, Rengo conducted a demonstration project targeting to secure a long-term stable supply of Japanese sweet potatoes. The packaging design focuses on two key aspects: traceability and the Product-of-Japan "label. For traceability, each box is equipped with digitally printed QR codes. Through these codes, Japanese and local associates can scan to check and compare the conditions of contents before shipment and after arrival. To emphasize the Product-of-Japan" aspect, the design was fixed inspired by the world of "manga," an iconic symbol of Japanese culture, creating a strong and appealing visual representation.

Mont Blanc Cake Transportation Box

- Kyowa Corrugated Cardboard Co., Ltd.

- Ginnomori. Co., Ltd

Usually, Mont Blanc Cakes are transported frozen, stored in a freezer upon arrival, thawed in a refrigerator before sale, and then displayed on store shelves. In the past, they were transported in Styrofoam boxes with bubble sheets and moved one by one to the refrigerator for thawing, which required water-absorbing mats to prevent condensation. Our challenges were to eliminate the usage of mats and dispose of packaging materials. The newly developed packaging is composed of a cardboard tray and outer box. By placing the cakes on the tray and storing them in the outer box, the bubble sheets have been eliminated, leading to improved transport efficiency. The whole tray can be moved directly from the freezer to the refrigerator, eliminating the need for water-absorbing mats and significantly improving workability and cost.

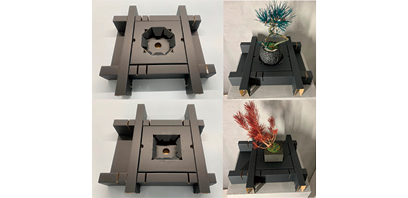

Tokocie BONSAI (For Bowls) Complementary Material

- Kawahara shiki Co., LTD.

- Ollivier Co., LTD.

A transport packaging adaptable for bonsais of various branching styles. In the past, the position of the pot had to be modified according to the branching, requiring the use of corrugated supplementary materials to secure the pot in place. To solve this problem, we have developed a corrugated, flexible partition through recombination. This innovation allows for the realization of 13 different storage patterns by simply adjusting the position of the partition (25 patterns are achievable by altering the front and back placements). The pad can contain both the pot and the base and the cutouts in the pad are adaptable for both round and square pots.

"Fingers Comfort" Handle Slots

- Dynapac Co., Ltd.

Cardboard boxes with handle slots on the sides are more convenient for users. However, existing handle slots design often cause discomfort or even pain to fingers and while handling them. To address this, we applied our existing technology, the Shimaoka Lock design to handle slots. Unlike common handle slots, the Shimaoka Lock design expands the contact area, using an inner fold flap, to reduce pressure and provide more comfort for the fingers when lifting the box. The inner fold flap is a three-dimensional shape folding structure that can be easily created with one hand by users themselves. As a result, we have achieved improved functionality along with enhanced workability.

Instant Open & Display! Carton

- Coca・Cola (Japan) Company, Limited

- Rengo Co., Ltd.

We have developed packaging based on 0201 type box that can be effortlessly opened and transformed into a tray using a corrugated perforation called the 'Corrumishin.' This innovative perforation, created by corrugators, minimizes deterioration in strength. Conventional corrugated carton for beverages and beer often includes liner cuts for ease of opening, but these are prone to breaking during the opening process. Besides, the use of perforations leads to a decrease in compression strength, and processing on the 0201 box had several issues. With our new structural design, just by lifting the top center opening triggers, the perforation on the side rips open and instantly creates a tray for easy and convenient display.

Saishunkan Pharmaceutical Plastic-free Mail Order E-Commerce Box

- Saishunkan Pharmaceutical Co., Ltd.

- Rengo Co., Ltd.

Package for e-commerce requires a high level of tampering prevention. That is why conventional packages had plastic binding bands on the outside to prevent unanticipated openings. However, in our pursuit of eco-friendliness, we aimed to eliminate the binding band and developed an innovative structure. On the top surface of the box is a locking mechanism applying a tuck-in flap structure. The female flap hole has slopes on both sides and the two ends of the male closure flap securely penetrate along them. The flap is firmly closed without the corrugated being crushed, which improves the lock function. Furthermore, we've implemented a similar lock mechanism on the bottom surface to enhance tamper prevention.

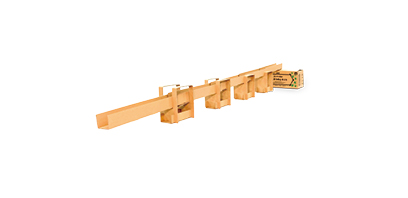

"Asahi Super Dry" Cardboard Box That Transforms into a Nagashi-Somen Kit.

- ASAHI BREWERIES, LTD.

- Oji Container Co., Ltd.

To provide exciting and novel experiences to consumers who purchase canned beer, we have developed innovative packaging that offers the enjoyment of Nagashi-Somen―a playful Japanese eating style of Somen noodles flowing in water―along with beer. Consumers utilize it with wrapping and aluminum foil to maintain hygiene and structural integrity. As Nagashi-Somen doesn't involve the use of fire, it's safe even for young children. Furthermore, it can be relished on balconies, in gardens, or on indoor tables, as it neither emits smoke nor generates odor, ensuring smiles for the entire family.

4-way Case for Vendor Products

- TOMOKU CO., LTD.

- ITO EN, LTD.

Workability is a critical concern for workers who load a large volume of products in vending machines each day. When unloading items from a truck using the 0201 type box, it was necessary to manually open the box to access the products, as the 0201 type box does not allow for easy retrieval from the side. The enhanced product offers four versatile usage options: 1) Open the top side of the short end to access the product without risking it falling during transportation. 2) Open the entire short side to retrieve the product. 3) Use it as a display tray. 4) Open both sides for easy disposal.

Transport and Display Box with Reduced Workability, Material While Having Promotional Effectiveness

- TOMOKU CO., LTD.

Corrugated assembly boxes, commonly used for transportation and display in large-scale stores due to their impressive shelf impact and product accessibility, face a challenge in balancing easy assembly and container strength efficiency. This innovative packaging solution, based on the 0201 box design, addresses this challenge by reducing assembly time and material usage while maintaining stacking strength through comprehensive frame support. The issues of convenient opening and ease of removal when stacked have been resolved by considering the insertion position of the top surface without compromising workability.

Electric Equipment Packaging Award

Development of Corrugated Cardboard Partition Trays with Reduced Environmental Impact

- SANRITSU CORPORATION

As part of our effort to reduce the size of endoscope packages, we are committed to lowering transportation costs and adopting eco-friendly materials. To pass the transport environmental test, the cushioning for storing the product has been miniaturized without changing the materials of EPP. The tray has been changed to recyclable corrugated cardboard to enhance eco-friendliness. This manually assembled packaging eliminates the need for tape for easy assembly, achieving a 20.7% reduction in volume and cost savings in transportation.

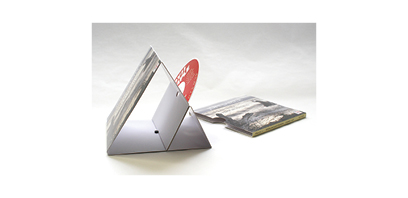

KABAJAKE

- DO PROJECT Co., Ltd.

- TOSHIKURA SEIHON Co., Ltd

A paper jacket designed to resemble a miniature vinyl record jacket has been developed for CDs. Since CDs are lighter than vinyl records, they often wouldn't come out smoothly from conventional paper jackets when shaken upside down. Additionally, fingerprints would frequently be left on the disc surface when handling with bare fingers. This innovative 'new paper jacket' offers easy disc removal and evokes the nostalgic charm of real record jackets while contributing to a plastic-free solution.

PowerShot V10 Product Box and Packing Material

- Canon Inc.

The packaging of this product is designed for worldwide shipping. We have improved the individual box design and materials in response to customers' demands, ensuring an enjoyable unboxing experience (e.g., unboxing videos on YouTube) and enabling customers to use their cameras immediately after unpacking. In light of the current global emphasis on Sustainable Development Goals (SDGs), our packaging poses a challenge in achieving a plastic-free solution, as it is crafted from plant-derived and paper-based materials, which encourages customers to select our product.

Beauty Humidifier Package with Collective Structure

- U-PACK Corporation

- KALTECH Corporation

We have developed an environmentally friendly packaging solution made entirely from corrugated materials for beauty humidifiers. This packaging is designed for easy assembly and optimized to accommodate all the contents, including multiple accessories, in a compact manner. Each accessory case is shaped with irregularities to fit together seamlessly, ensuring the secure packaging of the conical product with its many curved surfaces. This assembled structure solution provides complete protection for the entire product. Additionally, when accessories are not included, the packaging can be used without the accessory case.

Deplasticization! Fixing Pad "ECowrap" Using Stretchable Paper

- TOMOKU CO., LTD.

- Pack Tech Inc.

- Yokogawa Rental & Lease Corporation

Traditionally, computers of various shapes and sizes were transported using a securing material comprising flexible plastic films and cardboard pads. While conventional pads had the advantage of making products visible, they did not align with the SDGs trend, particularly the goal of reducing plastics. Therefore, we have replaced them with unbleached kraft paper, which is a crepe-processed paper with wrinkles. When stretched, this paper smooths out and can be expanded up to 1.5 times its original size. By transitioning from 'plastic film' to 'paper,' we have successfully developed an environmentally friendly securing pad with the same functionality.

Industrial Packaging Award

Contribute to Sustainability! Paper Ink Cartridge

- Mimaki Engineering Co., Ltd.

- Compack System Co., Ltd.

MIMAKI ENGINEERING CO., LTD., a manufacturer of industrial inkjet printers and related products, is committed to sustainability through resource-recycling management and technological advancement. This time, the material of the polypropylene ink cartridge has been replaced with paper (corrugated cardboard), while maintaining functionality. This switch has led to a reduction of approximately 68% in plastic usage. Consequently, the annual consumption of polypropylene resin has decreased by 29.2 tons, resulting in a notable reduction of approximately 38 tons of carbon dioxide emissions annually.

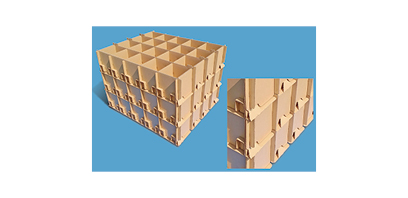

Inverted PAD with One-Touch Setup, Development of New "T-type Cross-lock" Technology

- Toyota Corrugated Packaging Industry Co.

In the automobile industry, corrugated plastic partitions are commonly used in logistics containers. We also employed these partitions with bottom pads known as inverted pads, to prevent contact between products during inter-factory transportation in returnable containers. However, their complex structure required additional time and labor in production. As a solution, we have introduced the 'T-shaped cross-lock' technology, which can be assembled with a single touch in just 2 seconds. As a result, the manufacturing process only requires press punching. This innovation has resulted in a remarkable 75% reduction in production time and approximately 40% cost savings.

Environmentally Friendly Packaging with Simple Insertion Structure

- DENSO AIRCOOL CORPORATION

The packaging of air conditioners designed for domestic base stations typically involves the use of a outer box with skid due to their weight, often exceeding 40 kg. However, due to the simplicity of the distribution route, we have optimized material usage while maintaining product quality to create an eco-friendly packaging solution. Key enhancements include (1) a lighter skid, (2) a weight-efficient upper pad that provides secure protection for the product, and (3) a simplified structure for both packing and unpacking accessories. As a result of these efforts, we have successfully reduced material usage by 45% and costs by 30%.

Lift Bracket Pallet

- Mitsubishi Logisnext Co., Ltd.

- Ailop Corp.

Lift brackets were traditionally shipped by laying them flat on a pallet and securing them with bands. Unfortunately, this approach often resulted in damages that required subsequent repaint. Furthermore, due to their non-stackable nature, trucks required racks to accommodate them. To address these challenges, we have introduced a dedicated pallet design that allows the product to be placed diagonally. The new design minimizes contact points and utilizes urethane to prevent damage. This innovative packaging solution permits loading three units per pallet without the need for banding. By eliminating the requirement for rack installations on truck beds, it also fosters versatility across 15 different product types, varying in size and shape.

Standardized Packaging for Distribution Boards

- TERADA. FAN Corporation

- TANAKA PAPER INDUSTRY CO., LTD.

This packaging has been standardized to accommodate two types of distribution boards with varying heights. In the previous design, cushioning components consisted of 3 pieces of styrene foam and 2 pieces of corrugated cardboard, each with different dimensions. However, in the newly developed packaging, a single corrugated cushioning material is employed for both the top and bottom sections. The packaging itself is entirely made of corrugated material, including accessory boxes and cushioning components. The assembly process for the cushioning is straightforward, resulting in a reduced work time from 7 minutes to 5 minutes. Furthermore, this optimization has led to a 20% reduction in required storage space for packaging materials.

New Packaging of Large-Diameter Photoreceptor Drums for Digital Printing Presses

- KYOCERA Corporation

The packaging for large-diameter photoreceptor drums has undergone significant improvements, addressing three key challenges: (1) enhancing usability, (2) achieving plastic-free solutions, and (3) successfully passing a drop test from 80 cm height. As a result, we have modified from vertical to horizontal insertion, adding handles for easy removal from the box. We have also completely replaced the cushioning materials with corrugated materials and implemented a brace structure to maintain cushioning performance despite the reduced box volume, passing with drop test requirements. Additionally, we have achieved a 2.4 times increase in loading efficiency (when using a T11 pallet with a 3m high stacking), reduced volume by 13%, and reduced CO2 emissions by 12.9%.

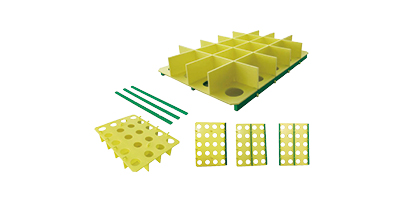

Seven Kinds of Trays for Robot

- TSK Corporation

The product is available in seven different shapes, with lengths ranging from 2 to 7, depending on the specifications. These products are picked by a robot arm and then returned to their original trays after processing. To develop the packaging, we needed to include positioning holes for the robot arm's picking process. Additionally, standardizing the tray's outer dimensions, stacking shape, and positioning holes was crucial for enabling automatic stacking. To address these requirements, we have developed a three-layer structure tray consisting of a common tray, seven types of basic trays, and a core tray to correspond to the vary of product size.

Stapleless Safe Packaging for Automotive Doors

- Toyota Motor Kyushu, Inc.

- CHUOH PACK INDUSTRY CO., LTD.

Traditionally, the packaging for automobile doors required the use of 8 staples in total. To enhance safety and reduce noise resulting from stapling, we have introduced stapleless packaging. This change has not only improved safety and workability by replacing staples with an inserting and locking mechanism (with a required packaging time of 3 seconds per unit) but has also created a noise-free work environment. Additionally, our newly developed doglegged packaging shape, designed to perfectly fit the product, increases number of contents from 3 units to 4 units per equipment, resulting in improved transportation efficiency.

Returnable-BOX for Triangular Pyramid Garnish

- TOYOTSU NEWPACK corporation

This is a returnable box designed for garnishes, which are interior parts for automobiles. Initially, the products didn't fit well within the designated box, resulting in significant unused space on the left and right sides and inefficient stowing with only two levels. To address this issue, we have improved the design by leveraging the triangular pyramid shape of the product. By placing each product alternately on one side, creating a triangular cross-sectional shape for each tray, we have reduced the overall height when the products are stored. Consequently, we can now accommodate an extra level compared to the previous design, thereby increasing stowing efficiency by 1.5 times.

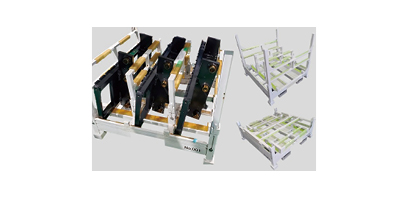

Brim Type Liquid Crystal Panel Packaging with PET Sheet

- SBS Toshiba Logistics Corporation

The packaging for LCD panels, which are made from thin glass plates, requires a significant amount of cushioning material to prevent them from cracking or being damaged during transportation. This results in high packaging material costs and poor transport efficiency. To protect the fragile parts of the product from coming into contact with the packaging components and becoming damaged, a slightly larger PET board than the panel has been attached to safeguard the contents. It is secured in place with a unique pocket mechanism integrated into the PET board. Additionally, this PET board reduces the need for cushioning material, enabling the storage of two products, effectively doubling the storage capacity and improving overall storage efficiency.

Roll Arm Pad Interior Material

- TOYOCON co., Ltd.

We have developed all cardboard boxes for six types of HDD packaging specifications with a focus on workability, as these boxes are used to securely protect precision equipment that often requires multiple unpacking and repacking cycles during transportation. The key features are 1) roll arm pad used as the interior material to enhance rigidity and reusability, 2) integrated upper and lower parts of the packaging, eliminating the need to disassemble components when unpacking, and 3) one-touch opening for easy product removal process. As a result of these improvements, we have achieved significant benefits, including a 10% reduction in material costs, a 25% reduction in packaging size, a 10% reduction in transportation costs, and a 50% reduction in work time.

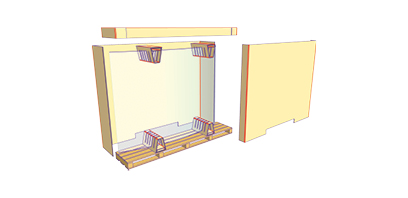

Improvement of Cleaning Work with a Lock Structure That Enables Quick Disassembly and Assembly

- SHINGOSHU CO., LTD.

We have enhanced the workability of packaging that requires regular cleaning. Previously, the assembly partition and round hole base were secured with Insulock ties, necessitating separation for cleaning and then reattachment with Insulock afterward. As a solution, we have made the supports attached to the backside edge removable, allowing them to be locked in place by rotating them 90 degrees. Additionally, the partition and the base are now separable. This solution eliminates the need for Insulock ties, resulting in several benefits: (1) improved cleaning efficiency, (2) the ability to replace damaged parts, and (3) enhanced quality due to reduced drying time after cleaning and increased rigidity achieved by using Durawood as the material.

Large-sized Equipment Packaging Award

Transportation Packing Box with the Slope for the Reagent Exchange Robot

- LOGISTEED, Ltd.

The reagent exchange robot (mass: 214 kg) is transported worldwide approximately twice a year. In response to the need for improved workability and disposability at the destination, we have made the following enhancements, utilizing environmentally friendly materials: 1) The content can be unloaded by simply lowering the slope. 2) Only plastic joints are utilized to secure the packaging, enhancing work efficiency. 3) Plywood has been incorporated in some parts to securely hold heavy products. 4) The skids have been modified from 2-way to 4-way, enabling easier handling.

Self-Standing Packaging for Transport Refrigeration Units (That will not fall down, even if the lashing is released.)

- Mitsubishi Heavy Industries Thermal Systems, LTD.

- MITA KOSAKU CO., LTD.

This is the newly developed packaging solution for a new model of the transport refrigeration unit, aimed at enhancing the efficiency of installation in vehicles. The previous packaging design had an issue with installation orientation, requiring the product to be turned around after unpacking and then lifted and supported since it wasn't stable on its own, resulting in additional work. With the new model, the unit stands independently in a half-unpacked state and can be directly installed in a vehicle, eliminating the need for additional work. The entire process, from transportation to vehicle installation, is now streamlined.

【Work efficiency improvement】Packaging for the Front Window of Mitsubishi Fuso Bus

- Oji Interpack Co., Ltd.

Large-sized and varying-designed front window for buses are typically transported in wooden crates, which raises poor workability and waste issues. Therefore, we have developed the packaging utilizing HiPLE-ACE and corrugated cardboard except the pallet. It achieved, (1) The front part can be opened and closed, simplifying the packing and unpacking process. (2) Plastic screws have been adopted for easier unpacking. (3) The curved glass can be transported upright to prevent any damage. These improvements have reduced material costs by 7% and work time by 50%, resulting in an annual cost reduction of 7,464,000 yen.

Safe Stacking Smart Container for Long Steel Products

- SBS Toshiba Logistics Corporation

This is the packaging solution for steel parts exceeding 3 meters in length, which were previously transported on wooden pallets. The process of loading and unloading using machines presented challenges and the potential for damage due to tipping or falling. Our newly innovated returnable container for long products now enables handling with a forklift, container crane, or hand-pushing with removable casters, improving workability both in the warehouse and during transportation. Additionally, the side frame is designed to open outward for easy packing, and a belt for securing items can be stowed when not in use.

HEV Car Battery Collective Packaging

- KARIYASHIKI Co., Ltd.

This packaging, designed for storing batteries used in hybrid electric vehicles (HEVs), possesses ample load-bearing strength even when three pallets, each with a maximum total weight of 430 kg, are stacked. This is made possible by a stack-slippage prevention fixing feature. The distinctive windmill-shaped partition, featuring an X-shaped design in the central portion, provides a dedicated space for removing the hangers used during product packing with the partition attached. Additionally, we have reduced the number of partition components, resulting in cost savings.

Development of Corrugated Cardboard Packing Material That Firmly Fixes and Protects Precision Parts for Aircraft

- NabiAce Co., Ltd.

The conventional wooden container weighted approximately 100 kg which was unstackable and caused several issues, including storage space constraints. To address these challenges, we have developed a new packaging utilizing 'NabiAce Plus', which securely fixes and protects the contents through unique upper and bottom components. The weight of the materials used has been reduced by 75%, enabling two-tier stacking and effectively doubling storage and transport efficiency. Additionally, we have achieved a 78% reduction in total CO2 emissions from the materials.

Triangle Structure Partition That Is Strong Even If It Shifts

- DENSO LOGITEM CORPORATION

- TOKAISHIKI CORPORATION

When exporting heavy automotive parts such as alternators, we frequently encountered cargo collapse. These incidents caused inconvenience for customers and posed safety risks for those involved in logistics. In order to address this problem, we have implemented a new reinforced structure that utilizes alternative materials to reduce both weight and cost. The partition plates stacked inside the container are designed to prevent collapse and maintain structural integrity, by keeping the upper plate even if displacement occurs.

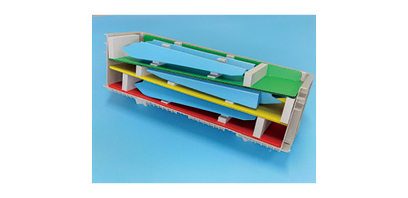

Improving the Packaging of Film for Export

- RIKEN TECHNOS CORP.

- MOTEGI CO., LTD.

- ASANO CORRUGATED BOARD CO., LTD.

The packaging for large industrial films for export was enclosed in a 0201-type outer box along with an additional reinforcing sleeve. This resulted in double packaging that required a significant amount of materials and time for installing the sleeve and taping. As a result, we have optimized the packaging to reduce material usage and workload. By combining assembled trays and a sleeve, the amount of material has been reduced by approximately 68%, and work efficiency has been improved by approximately 20%, resulting in a cost reduction of approximately 40%.