Minister of Economy, Trade and Industry Award

Panasonic Battery Evolta/Evolta Neo Series Ethical Packages

- Panasonic Energy Co., Ltd.

To reduce the volume of packaging materials and excessive plastic and paper use, we have developed eco-friendly packaging that offers added benefits to consumers. Our innovative packaging includes the following key features: 1) Introduction of paper bag packages for dry cell batteries for the first time. 2) A significant reduction in packaging materials by 38% to 60% across various sales sizes. 3) Facilitation of global business expansion through the availability of simple facilities. 4) Realistic printing on the paper package to complement concealed contents. 5) Approximately 19-ton reduction in packaging materials per year, contributing to a decrease in CO2 emissions.

Director of General, Industrial Science and Technology Policy and Environment Bureau, Ministry of Economy, Trade and Industry Award

The World's First! 100% Recycled Aluminum Can

- Suntory Holdings Limited

- Toyo Seikan Group Holdings,Ltd.

- UACJ Corporation

This innovative aluminum can is made entirely from 100% recycled materials, including both the body and the lid. This solution leads to a remarkable 60% reduction in CO2 emissions compared to conventional aluminum cans. Maintaining same specifications as standard cans, it can be produced in existing factories without requiring any special modifications. This is the world's first SOT (Stay On Tab) aluminum can launched in the market, revolutionizing the use of 100% recycled materials for both its body and lid.

Director of General, Manufacturing Industries Bureau, Ministry of Economy, Trade and Industry Award

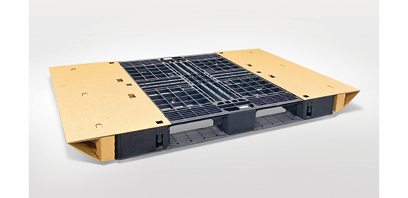

Expandable Corrugated Sheet for Standard Pallet

- Rengo Co., Ltd.

We developed an innovative adjustable corrugated component that can expand in various sizes to match the dimensions of cargo products loaded on pallets. It protects overhanging stocked products on pallets from deformation. By attaching these expansion parts to a standard 1,200mm x 1,000mm plastic pallet―a prevalent specification in the Asian market―the pallet size can be expanded as needed. Preventing cargo deformation leads to improvement of storage conditions and transportation efficiency. Attaching and removing, both processes are very simple and this innovative component also enhances pallet recycling and reusability.

President of Japan Chamber of Commerce and Industry Award

ClearX® -High Performance Syringe system-

- TAISEIKAKO CO., LTD.

ClearX® has been specifically developed for pre-filled syringes, offering benefits that include reduced operation time, prevention of foreign substance contamination, and the assurance of safe and effortless injections. The ClearX® piston effortlessly slides and dispenses the inner drug without the need for silicone lubrication in the syringe. The chosen material exhibits extremely low adsorption properties to ensure the stable storage of the drug solution, minimizing the risks of agglomeration and drug adsorption, thereby enhancing patient safety. Additionally, this syringe system is compatible with both vacuum stoppering and sleeve stoppering methods, effectively reducing the presence of air bubbles during the drug solution filling process.

Chairman of Japan External Trade Organization (JETRO) Award

Corrugated Bandless Container with Significantly Increased Loading Weight

~ Emergency Response to Chaos in International Logistics (Switching from Steel to Cardboard) ~

- TOYOTA MOTOR CORPORATION

- DAIEI Co., Ltd.

- NabiAce Co., Ltd.

In the past, the products were exported using returnable steel containers. However, their shortage due to global disruption in logistics caused a problem of shipping. To solve this issue, we have developed a one-way container made of corrugated material. This container can correspond to sudden changes in goods quantity while maintaining loading capacity, work efficiency, and container loading efficiency. It features easy assembly, reduced labor work, elimination of banding, no need for secondary materials, safe compressive strength even when stacked three high, 44% reduction in packaging material weight and 72% reduction in CO2 emissions annually.

President of Japan Productivity Center for Socio-Economic Development Award

High Performance Cushioning Material Made from Used Copy Paper!

- SEIKO EPSON CORPORATION

We have developed eco-friendly paper cushioning components to replace petroleum-derived materials. Our solution utilizes discarded copy papers collected through an in-house wastepaper system. These papers are transformed into fibers using our proprietary 'dry fiber technology,' which minimizes water usage. This process enables us to create cushioning material with optimized performance and design, equivalent to or surpassing high-performance petroleum-based options. Our innovative solution offers shock-absorbing properties comparable to traditional materials and maintains the same cushioning efficiency. As a result, conventional outer boxes can be employed without resizing, leading to efficient material utilization. This sustainable packaging solution is currently implemented for printers.

Japan Package Design Association Award

SHISEIDO EUDERMINE LiquiForm Bottle

- SHISEIDO CO., LTD.

- YOSHINO KOGYOSHO CO., LTD.

A revolutionary technology known as 'LiquiForm®' has introduced a groundbreaking approach to cosmetics by combining 'bottle manufacturing' and 'liquid content filling' into a single step. Thanks to this technology, the weight of refill containers is significantly reduced, resulting in a 70% decrease in plastic usage and CO2 emissions throughout the packaging lifecycle compared to our conventional refill containers of the same capacity. Additionally, this packaging offers both a premium touch and feel and environmental consciousness simultaneously, achieved through its high-quality design and user-friendly refill mechanism.

President of Japan Marketing Association Award

TOPPAN Bread Package

- SakimotoBakery Co., Ltd.

- TOPPAN Inc.

As part of a strategic PR initiative aimed at showcasing TOPPAN as a pioneering company that embraces societal challenges, we've partnered with SakimotoBakery to develop a product addressing the issue of food waste by extending shelf life. Utilizing the transparent barrier film GL BARRIER, created through TOPPAN's transparent vapor deposition processing technology and coating expertise, we have achieved an impressive sevenfold extension in the product's shelf life. The attractive design highlights its transparent properties, showing the bread enriched with vegetables―ingredients that are often wasted. To commemorate the International Day of Awareness for Food Loss and Waste, we distributed this innovative bread in Akihabara, resulting in a highly impactful PR campaign.

Japan Graphic Design Association Award

Cle de peau BEAUTE Lune Joaillier

- SHISEIDO CO., LTD.

- HIDAN CO., LTD.

A special collection born from collaboration with Mr. Elie Top, a jeweler from Paris, France, commemorating our brand's 40th anniversary. This collection features a set of four lipstick refills, a lip holder, and a moon-like compact mirror. The cap employs a magnetic closure, evoking the ritualistic experience of opening a traditional Japanese tea canister―an action that carries a sense of vacuum and depth, compelling one to repeat the motion. Removing the refill is effortless by simply inserting it into the lip holder, granting you the freedom to select your preferred color. The lip holder itself features electroformed and potted details on both its front and back, capturing the essence of a 'moon emitting a solemn light.' In addition to being refillable, PIR (Post-Industrial Recycled) resin is used for temporary caps, contributing to a reduction in the amount of virgin plastic used.

President of The Accessible Design Foundation of Japan Award

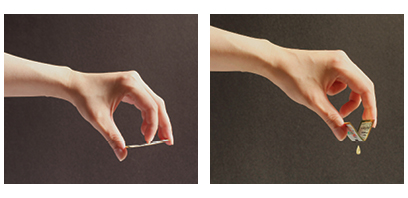

VS PAK

- V PAK Corporation

- SEIWA HOLDINGS Co., Ltd.

- FUTURE LABO Inc.

- KAISHIN Inc.

This is a cost-effective, universally designed individual packaging with barrier properties. It can be easily opened with one hand by bending it into a V shape and breaking the AL (sealing material) at the opening to dispense the contents. It's user-friendly, facilitates easy pouring, and maintains hygiene since consumers don't come into contact with the contents. It can be used for individual packaging containing liquids, powders, granules, etc., in pharmaceuticals, cosmetics, foods, and everyday items. Additionally, it supports retort sterilization due to the composite film.

Consumer Associations Award

Silcot Wet Tissue Dispenser Series

- Unicharm Corporation

- Dai Nippon Printing Co., Ltd.

We have created a horizontal box-type wet wipe container that excels in airtight sealing, accessibility, effortless extraction, and remarkable design. In terms of functionality, it features an impressively airtight design, thanks to a soft packing on the lid seal and a tapered ring on the main body. The thoughtfully designed outlet facilitates sheet retrieval and resetting by allowing the insertion of a finger directly to remove fallen sheets. Furthermore, it includes a braking function to suppress repetitive vibrations through the bow spring mechanism of the lid when fully opened, and it offers a premium feel by incorporating fine leather texture processing to minimize scratches and plastic-like impressions.

President of Japan Packaging Institute Award

Packing Trays for Large Commercial Air Conditioner Indoor Units Assemblable by Automatic Machine

- DAIKIN INDUSTRIES, LTD.

- Oji Container Co., Ltd.

- Oji Holdings Corporation

Corrugated cardboard packing trays for commercial ceiling cassette air conditioners used to be assembled manually from the top and bottom of the product due to their intricate design. To address this, we have developed trays that can be assembled automatically, along with a corresponding machine―a first-of-its-kind in the packaging industry in Japan. These trays are among the largest in size. The machine accomplishes both automated assembly and packing processes, including tray picking, automated assembly for creating holding trays, and direct integration with the existing automatic packaging line. As a result, we have reduced assembly labor by 40% and reduced assembly time by 33%.

President of Japan Packaging Institute Award

OKAERI Refill Pack

- Kao Corporation

- Lion Corporation

- Fuji Seal, Inc.

- Mitsui Chemicals, Inc.

- Prime Polymer Co., Ltd.

- Tosoh Corporation

Multi-layered pouch containers made from various materials have significantly contributed to reducing plastic usage. However, the combination of these materials has presented challenges in recycling. To promote a circular economy for plastic packaging, an innovative pouch to pouch recycling technology was examined starting from the collection of used pouches. The techniques for separating different materials and enhancing resin purity were developed through this study. Finally, a world-first pouch to pouch recycling was achieved with the collaboration of multiple companies. This breakthrough has enabled the recycling of multi-layered pouches, which were previously considered difficult to recycle, and has allowed to achieve both waste reduction and recycling goals.