Minister of Economy, Trade and Industry Award

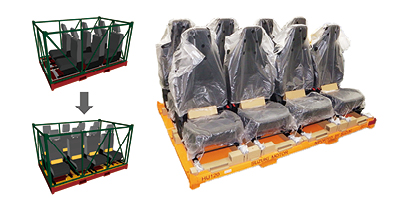

Improving the use of full cardboard in the transport fixation of Seats for overseas shipments

- Suzuki Motor Corporation

- Oji Container Co., Ltd

The shipping method of seats for overseas had the following problems.

①accommodation efficiency ②high cost due to steel

③Less workability because the seat must slide when fixed and 36 bolts must be tightened

This time, with the adoption of lightweight, design-freedom and easy-to-recycle cardboard boxes,

①Development of jump-up prevention structure, increased number of contents from 6 to 8 seats / case

②Cost reduction and recycling ③Abolition of sliding work and bolting in fixing

These improvements were made to achieve an annual effect of - 30 million yen.

Director of General, Industrial Science and Technology Policy and Environment Bureau, Ministry of Economy, Trade and Industry Award

PE Monomaterial Refill Pouch: New PANTENE effortless series

- FUJIMORI KOGYO Co., LTD.

- P&G Japan (The Procter&Gamble Company of Japan Limited)

Conventional refill pouches are typically made of multiple films laminated together. These are difficult to separate after use, which makes them difficult to recycle. To solve this issue, we began a challenging work to make monomaterial pouches for liquids.

After much trial and error, we succeeded in making pouches out of only polyethylene, and these are easy to recycle.

The pouches are currently being sold through various channels as a sustainable solution, thereby contributing to the expansion of recyclable monomaterial packaging.

Director of General, Manufacturing Industries Bureau, Ministry of Economy, Trade and Industry Award

Easy Sealing with Shipping Slip "FukuLock"

- Rengo Co., Ltd.

In the growing field of e-commerce, simplification of packing operations is an important issue and an efficient design is highly required. To solve this problem, we have developed package to reduce the material costs which rise along with the increasing distribution amount, and to appeal to end users with heightened environmental awareness. As a result, compared to the conventional 0215 top with one-touch box mechanism, the interlocking of the outer flap and inner flap, and sealing with a shipping slip have been improved for workability and the flap structure has been developed to reduce the area of material used and to lower the costs and CO2 emissions. In addition, the outer flap can be inserted into the inner flap, which saves space and enhances disposability when folded.

President of Japan Chamber of Commerce and Industry Award

Paper Packaging for Hato Sable: Paper Pillow Packages

- Toshimaya Co., Ltd.

- NIPPON PAPER INDUSTRIES CO.,LTD.

To contribute to the reduction of single-use plastics and carbon neutrality, from October 2021, the 8-piece pillow packaging of Kamakura's famous confectionery Hato Sable will be made from paper. Since typical pillow packaging machines were exclusively for film, the packaging machine has been modified to accommodate paper. This product is the pioneer of large paper bags that are automatically wrapped by the horizontal pillow type (a type in which sweets are gently filled from the side) according to in-house research.

Chairman of Japan External Trade Organization (JETRO) Award

Lithium-ion Battery: 100% Recycled EPS and Minimized Storage

- TOSHIBA CORPORATION

- SBS TOSHIBA LOGISTICS CORPORATION

- SEKISUI KASEI CO., LTD.

In the packaging of lithium-ion batteries, which are attracting attention as storage batteries for renewable energy, we worked to replace virgin materials with 100% recycled EPS, which complies with packaging waste regulations in Europe and the United States, and met the prescribed packaging cargo test conditions. However, by minimizing the product storage interval, the number of products stored per package has been improved. As a result, transportation efficiency has been improved by 25%, foam packaging material usage per product has been reduced by 5.7%, transportation cost and CO2 emissions during transportation by 20%, and package material cost by 40%.

President of Japan Productivity Center for Socio-Economic Development Award

Just Roll and Bend: Packing Weatherproof Covers Using Simple Corner Cushioning Material

- HORKOS CORP

- Dynapac Co.,Ltd.

Previously, our weatherproof covers were made with a Styrofoam pad adhered on a cardboard sheet but posed issues such as labor cost of waste sorting on-site and better reduction of chemical waste. As an eco-friendly corrugated cardboard cushioning material that can be easily sorted, we have adopted a Pakitto Corner structure that is easy to assemble by simply rolling and bending, enabling the reduction of overall cost by standardizing the corner cushioning material.

Japan Package Design Association Award

WASO Series

- SHISEIDO CO.,LTD

- YOSHIDA COSMEWORKS Co.,Ltd.

- YOSHINO KOGYOSHO CO., LTD.

WASO aims to create products that not only improve the condition of the skin from within, but also support a sustainable future through clean and sustainable packaging.

We have developed packaging that utilizes sustainable materials (Upcycled & Recycled & Biomass), such as a 30% rice husk-derived outer cap, a 100% recycled-PET outer container, and bio-PE blended tubes. Using a refillable container has reduced the amount of plastic waste by 89% compared to the specific weight.

President of Japan Marketing Association Award

LOOK Plus Awa-Pita Toilet Cleaning Spray

- Lion Corporation

- YOSHINO KOGYOSHO CO.,LTD.

Toilet cleaning spray Awa-Pita can effectively clean an entire toilet by the new simple steps of spraying thick foam that reaches the dirty inner edges of toilet bowls and leaving it for a minute. In order to realize not only a strong spray that can deliver foam to the inner edge, but to be user-friendly for anyone, we adopted a pressure accumulation type foam trigger. The lever has two functions; when it is pulled slowly, a fluffy foam appropriate for cleaning the toilet bowl and seat comes out and stays in place, and when pulled quickly, a loose foam comes out to clean the floor easily. A tilting component is attached inside the trigger, so spraying is also possible with the bottle tilted or upside-down.

Japan Graphic Design Association Award

SHISEIDO Ultimune Refill 100% Recycled Glass

- SHISEIDO CO., LTD

- NIHON TAISANBIN GLASS BOTTLE MFG CO.,LTD.

- YOSHINO KOGYOSHO CO., LTD.

For the first time, Shiseido has adopted 100% recycled glass for the refill container of Ultimune for its renewal launch, aiming to upgrade sustainability. Incorporating a plant-derived resin to the cap and realizing a bottle made entirely of recycled glass can contribute to reducing environmental impact. This glass bottle maintains Ultimune's luxurious clear appearance while using only recycled glass. The use of refills has reduced the amount of plastic waste by 95%* (*body weight ratio).

President of The Accessible Design Foundation of Japan Award

Grab and Quick Open!: V-Link Zipper

- Rengo Co., Ltd.

This inner carton for products such as confectioneries, retort food pouches, and jelly pouches with spouts can be easily opened in a second by anyone, providing a safe and clean edge half-tray after opening. To open and separate the box, grab and push the opening on the back to form a V-shape which transmits the opening force to both sides, then pull it up. That way, it can be easily separated with little force. The opening is located close to the top, so that anyone can grasp it regardless of hand size and can apply force easily. The cut edge after opening is rounded not to hurt the fingers when touched and to provide a good appearance.

Consumer Associations Award

Green Base Dry Veggie Series

- ELLEROSE Co., Ltd.

- THE PACK CORPORATION

We have adopted kraft-clear packaging for dried vegetables produced domestically that are delicious while contributing to reducing food loss. By using highly transparent paper for more than 50%, it allows to be labelled as paper packaging and the inside product is visible along with oxygen barrier coating. Flexographic printing, which uses fewer organic solvents, has been adopted in consideration of the environment.

President of Japan Packaging Institute Award

Jagabee

- Calbee, Inc.

- Toppan Inc.

ECOLUSTER®, an eco-friendly offset printing that combines oil-based biomass ink and water-based pack varnish, has been adopted for the carton printing of Jagabee. ECOLUSTER® can print with the same lead time as UV printing, greatly improving productivity compared to conventional oil-based printing. Biomass inks derived from plants are used, allowing for the biomass marks and vegetable oil ink marks to be applied. CO2 emissions derived from raw ink materials and the printing process can be reduced by approximately 34% compared to UV offset printing. Using FSC-certified paper for the package, it can also appeal to consumers at stores as an eco-friendly product.

President of Japan Packaging Institute Award

Environmentally Friendly Laminated Tube

- AOHATA Corporation

- Dai Nippon Printing Co., Ltd.

We have developed eco-friendly laminated tubes reducing plastic and using biomass materials for our mainstay laminated tube products. By making the plastic resin used in the body of the laminated tube thinner, the amount of plastic used has been reduced by approximately 9.3% (compared to previous tube part) and CO2 emitted during tube manufacturing by approximately 4.9%. In addition, the gravure ink used for printing has been partially changed from petroleum-derived ink to plant-derived biomass ink. While we have been struggled to maintain the integrity of the container, preservability of the contents and productivity as it is thinner than previous products, we have commercialized the product by adjusting the container manufacturing process and production line.